|

||||||||

6.2

Design of Condenser

The condenser/ evaporator must be designed in such a way that the

ammonia vapor, when condensed, can be stored in it. Therefore, the volume of

the condenser/evaporator must be at least 2.5 liters, which is the quantity of

ammonia required to convert 5 liters of water into ice.

The dimensions of the inner tank. Which holds ice, is as follows:

Length = 24.5 cm

Breath = 25 cm

Height = 8 cm

Considering allowance, the height of tank is 12 cm

The volume of the condenser is

Vc = p/4 [4d2 b lb + 6 d2c

lc + 16d2v lv]

Where

|

db |

= = |

Inside dia.

Of the pipe of the bottom frame f

5.08 cm |

|

dc |

= = |

Inside dia.

of the cross pipes f

1.27 cm |

|

dv |

= = |

Inside dia

of the vertical pipes f

1.27 cm |

|

lc |

= = |

Length of

each cross pipe 25 cm |

|

Lv |

= = |

Length of

each vertical pipe 8 cm |

Vc = p/4 [4

( 5.08)2 (32) + 6(1.27)2 (25) + 16(1.27)2 (8) ]

= 2946.5 cm3

= 2.95 liters

Since the volume of the condenser is more than the volume of condensed ammonia required, the design is safe

6.3

Insulation

Thickness

of thermocol = 45 mm

(at the

top and bottom)

thickness

of glass wool = 85 mm

(At the

sides)

7.1. Flat Plate Collector:

(a) Collector Tubes and Header:

Two G.I tubes, one of which is f 5.08 cm

and the other f10.16 cm,

and length 112 cm were taken. Twelve holes were drilled on each pipe to

accommodate the end of the collector tubes of f1.27 cm. The G.I pipes of f 5.08 cm forms the lower header and that of f 10.16 cm

forms the upper header. These two

headers were connected by G.I pipes of f 1.27 cm. The ends of f 1.27 cm pipes were gas-welded with the headers. The upper

header was provided with two f 1.27 cm

pipes, one for charging of aqua-ammonia solution and the other for carrying

ammonia vapour to the condenser. The lower header was provided with one f 1.27 cm

pipe for the return line.

(b) Absorber plate:

The absorber plate was made from a

24-gauge aluminium sheet. The sheet was corrugated so as to accommodate the 12

G>I tubes of 1.27 cm. This was accomplished by carving a semi-circular

groove on a wooden block over which the aluminium sheet was placed on the

aluminium sheet over the groove . the rod was then hammered along the length

until the sheet was corrugated to the required shape . this was done at ten

desired positions along the width of the sheet ,the pitch being maintained at

10 cm.

Dimensions

of the absorber plate

|

Length |

= |

121.92

cm |

|

Width |

= |

91.44 cm |

|

Area |

= |

1.115 m2 |

Holes were

punched by the side of the grooves to facilitate the collector plate to be tied

to the tubes.

The

absorber plate was then placed on to the tubes such that the grooves covered

the ten tubes , leaving out one tube at each side to facilitate convection

.wires were then passed through the holes and around the tubes and the absorber

plate. Black board paint was then applied to the upper surface of the plate.

This type of contact between the absorber plate and the collector tubes ensures a god bond and heat transfer. However, the air gap small it may be, will itself form insulation and hence, decrease in plate efficiency is inevitable. Also, if the bond is good, all the heat is collected by the plate should be transferred to the working medium only through this small contact. This turns out to be a very inefficient method. However, soldered bond is expensive and heating and cooling of the pipes may result in cracks being developed at the joints.

(c) Collector case:

The collector case was made of plywood of size

143.2cm x

120cm x 20.32cm. The bottom was covered with plywood board of size 143.2cm x

120cm. The top was covered with a glass plate and frame, which was hinged to

one of the longer sides.

The collector tubes and absorber plate

assembly was placed in this case after packing the case with a layer of glass

wool of 8cm. Thickness. As mentioned earlier, only 10 pipes were covered with

the absorber plate, leaving out one at each side. These two pipes were also

insulated with glass wool, so that they do not get heated. This facilitates the

convection current to be set up inside the collector tubes, so that the

aqua-ammonia solution gets heated and ammonia is liberated.

Glass cover with frame:

Ordinary window glass of size

110cm x 110cm x 0.3cm was used. This glass cover was placed at a distance of

8cm above the absorber plate.

Shalimar tar-wax was applied to the top edges of the case to

form a layer of 0.3cm thickness and 0.6cm width. When the frame rests on the

edge, an air tight seal is obtained at the place of contact. It also acts as a

cushion to the glass plate.

Orientation of the collector:

The collector assembly was placed with an angle of tilt of

300 and facing south. The collector was turned at an angle of 80

towards west to take advantage of the afternoon sun.

7.2 Condenser

The condenser was made from G.I.

pipes of f1.27cm, f2.54cm and

f

5.08cm.firstly,two square frames of pipes were made, one from f2.24cm

pipe and the other from f5.08cm

pipe. Each pipe was cut into four pieces of required length at an angle of 450

to the axis of the pipe. The ends were then welded to form a square frame. The

lower frame was made from f5.08cm

pipe and the upper frame from f2.54cm

pipe.

The next step was to connect the

square frames together. For this, sixteen holes were drilled on each frame and

facing each other so as to accommodate the ends of sixteen f1.27cm

pipes were gas welded on to the square frames after positioning them properly

in the holes.

Six G.I pipes of f1.27cm

gas-welded to the two opposite pipes of the lower frame, which were provided

with the required size holes.

Two f1.27cm G.I. pipes were used as the inlet and outlet for

ammonia vapour, and were gas-welded on to the top of the frame.

A tank was made from G.I sheet, such that it fitted inside the

condenser. The dimensions of the tank are

|

Length |

: |

24.5cm |

|

Breath |

: |

25cm |

|

Height |

: |

12cm |

Water, which is to be cooled to

form ice, is to be filled only to height of 8cm so that the volume is 5 liters.

Stagnant water jacket:

If stagnant water is used for

cooling the condenser, then large quantity of water is required for efficient

condensation. A separate tank has to be provided for this purpose. So, a tank

of G.I> sheet was made to the following dimensions.

|

Length |

= |

43.2cm |

|

Breath |

= |

43.2cm |

|

Height |

= |

22.8cm |

A lid was provided at the top to

facilitate the insertion and removal of the inner tank. The top of the tank was

covered with thermocol and the sides were insulated by glass wool. The whole

set up was enclosed in a box made of hard board of 6mm thickness.

Structures

Structures were provided to hold

the collector and condenser in place. The condenser was placed at a higher

level with respect to the collector to prevent the aqua–ammonia solution from

getting into the condenser.

Connecting Pipes

The collector and condenser were

connected by means of f 1.27 cm

G.I. pipes. The outlet from the upper header of collector was connected to the

inlet of the condenser via a 1.2m. Rectifying column made from 1.27 cm G.I

pipe. The outlet of the condenser was connected to the inlet of the lower

header of the collector.

Valves

Stop values made of cast iron body

and steel ball valve inside were provided to regulate the flow of ammonia from

the collector to the condenser and back.

8

Instrumentation

Thermometers were used to measure

a. The

temperature of the absorber plate

b. The

temperature of the condenser

c. The

ambient temperature

8.2 Experimental Procedure

The apparatus was made leak proof

by applying shellac at the pipe joints. It was then charged with aqua–ammonia

solution and the charging valve was closed.

The temperature of the absorber

plate was measured and recorded and corresponding ambient temperature were

noted.

During nighttime, refrigeration

took place. The temperature of the condenser was noted in the morning the next

day. The readings were then tabulated.

RESULTS

PERFORMANCE

TEST

Date:

-------------

|

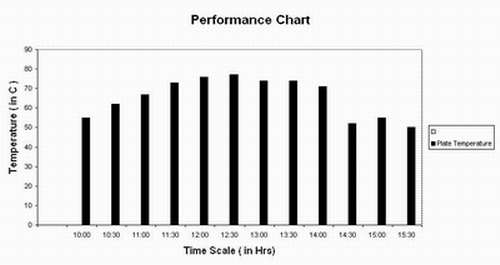

TIME |

PLATE TEMPERATURE IN 0C |

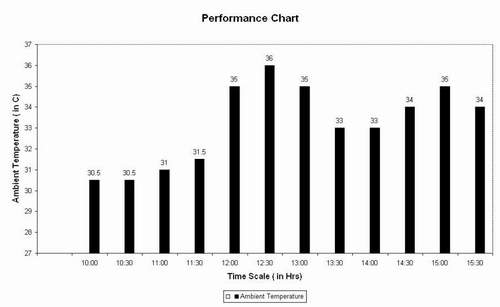

AMBIENT TEMPERATURE IN 0C |

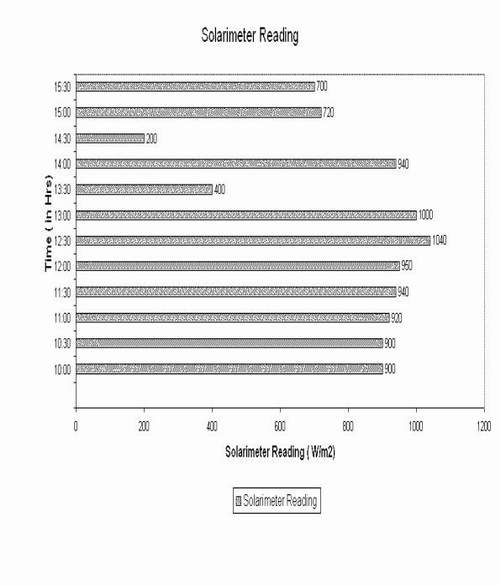

SOLARIMETER READING IN W/m2 |

|

|

|

|

|

|

10–00 AM |

55.0 |

30.5 |

900 |

|

10–30 AM |

62.0 |

30.5 |

900 |

|

11–00 AM |

67.0 |

31.0 |

920 |

|

11–30 AM |

73.0 |

31.5 |

940 |

|

12–00 AM |

76.0 |

35.0 |

950 |

|

12–30 AM |

77.0 |

36.0 |

1040 |

|

01–00 AM |

74.0 |

35.0 |

1000 |

|

01–30 AM |

74.0 |

33.0 |

400 |

|

02–00 AM |

71.0 |

33.0 |

940 |

|

02–30 AM |

52.0 |

34.0 |

200 |

|

03–00 AM |

55.0 |

35.0 |

720 |

|

03–30 AM |

50.0 |

34.0 |

700 |

At 6.00 pm water was filled in the

inner tank of the condenser at 280C.

At 12.30 am the temperature of

water was 240C.

At 6.30 am the temperature of

water was 200C.

This unit can be used in rural

areas where electricity is not available. This unit is simple to operate.

The unit was designed to produce

ice. However, we were able to get only chilled water.

The coat of the set–up is very

high. If solar refrigerators can be made on large scale, the cost of each unit

can be effectively reduced and used economically in rural areas.

SUGGESTION FOR IMPROVENT

Some improvement have been

proposed, but I was not applied due to technical difficulties, shortage of time

and non–availability of materials and equipments. These are as follows:

1. Double glazing can be used

instead of single glazing, so that the heat loss can be reduced and hence

efficiency can be increased.

2. Mirrors can be used to

concentrate the solar radiation on the absorber plate.

3. the air from the set–up must be

removed prior to charging.

4. A drain valve must be provided

between the condenser– evaporator and generator – absorber o drain out the

condensed water.

5. An array of the plate

collectors can be used tp increase the collector area.

10.

ECONIMIC ANALYSIS

COLLECTOR

|

4” GI pipes 1.1 meters |

|

|

|

|

2” GI pipes 1.1 meters |

|

|

|

|

½” GI pipes 20 meters |

|

|

|

|

Glass plate (1.1 x1.1 meters ) x0.3 mm thick |

|

|

|

|

Aluminium sheet(4’ x 3’) |

|

|

|

|

Black board paint(200 ml) |

|

|

|

|

Wooden planks |

|

|

|

|

Labour for wooden box |

|

|

|

|

Labour and gas welding material |

|

|

|

|

Paint(green) |

|

|

|

|

Steel wires,hinges,latches etc. |

|

|

|

|

Valves (4 in number)1/2” inch |

|

|

|

|

Cardboard |

|

|

|

|

Aqua–ammonia solution (10

liters) |

|

|

|

|

CONDENSER |

|

|

|

|

2” GI pipes 4”6’ |

|

|

|

|

1” GI pipes 4”8’ |

|

|

|

|

½” GI pipes 8” |

|

|

|

|

Gas welding material and labour |

|

|

|

|

Thermocol |

|

|

|

|

GI sheet and labour charge for

condenser tank |

|

|

|

|

Card board condenser box |

|

|

|

|

Fevicol |

|

|

|

|

Hinges, latches and screws |

|

|

|

|

Wooden stripes (1/2” x

1/2") |

|

|

|

|

Labour for card board box |

|

|

|

|

Drilling of holes |

|

|

|

|

|

|

|

|

|

Structures

for collector and condenser |

|

|

|

|

900 angle plates to

collector ( 11 m) |

|

|

|

|

900 angle plates for

ondenser |

|

|

|

|

¾” ms rod (21 kg) |

|

|

|

|

2” x ¼” MS flat bar (15 kg) |

|

|

|

|

PROJECT REPORT (-------------) |

|

|

|

|

OTHER CHARGES |

|

|

|

|

Elbows |

|

|

|

|

Wooden planks Painting charges |

|

|

|

|

Traveling charges |

|

|

|

|

Miscellaneous |

|

|

|

|

Arc welding rods |

|

|

|

|

Synopsis charge |

|

|

|

|

GARND TOTAL: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

11.

TARGET APPLICATION

For vaccine

storage and medical uses:

The World

Health Organization’s Global Programme for Vaccines and Immunization and its Expanded Programme on Immunization/EPI

has approved a number of low voltage DC PV vaccine refrigerators. Solar vaccine

refrigerators are designed specifically to meet health needs, and are not

appropriate for private use (e.g., refrigerating food and drink).

Technology

Availability:

The WHO has certified a number of models from

companies in the world for their GPV/EPI programmes. PV fridges and freezers

are generally only available on order from source manufacturers.

Fuel/Energy

Availability:

Most areas in the tropics have

sufficient solar energy availability for PV vaccine refrigeration systems.

Individual systems may have to be designed based on particular needs of the

clinic or health Programme.

Optimum

Situation:

Off-grid rural health clinics and hospitals with more than 4 kWh/m2/day solar radiation. Note that there must be sufficient technical infrastructure and manpower in place to service, monitor, and maintain the fridges. In cases where infrastructure is insufficient, consider LPG or kerosene fridges.

REFERENCES

|

SR NO |

INDUSTRY |

ADDRESS |

||

|

1 |

Jade

Mountain Inc http://www.jademountain.com |

P.O. Box 4616, Boulder, CO

80306 US |

||

|

2 |

Small

Power Systems |

74550

Dobie Lane |

||

|

|

|

|

||

|

|

BOOKS |

AUTHOR |

||

|

1 |

Refrigerator Handbook |

Operation and Maintenance

Manual, Whirlpool |

||

|

2 |

Guide to Insulations |

Dupont |

||

|

3 |

Solar Energy 5(1),(1961) ; Solar Energy 6(4), (1962) |

Prof. J.C.V. Chinnappa

|

||

|

|

|

|

||

|

4 |

Refrigeration and Air

Conditioning |

Domkhundwar |

||

|

|

||||

|

|

CASE STUDY |

AUTHOR |

||

|

|

|

|

||

|

1 |

Creating

a Renewable Energy Future |

Keith

Lee Kozloff and Roger C. Dower |

||

|

2 |

Bringing

Power to the People |

Daniel

M. Kammen |

||

|

3 |

Energy

Needs in Developing Countries and Sustainability |

José

Goldemberg |

||

| PAGE 3 | |||||||||

2002©Arma Technologies, all rights reserved disclaimer & copyright

If you find any of your copyrighted content email us the same along with proper proof ,the requisite material will be removed within a week