|

||||||||

4.

METHODOLOGY

Our aim is to develop a non-electric

solar refrigerator-freezer. The refrigerator uses an aqua-ammonia absorption

system similar to that used in propane refrigerators. The refrigerator consists

of two separate units; the solar collector-generator and the refrigerator box.

The collector-generator

consists of a thermal solar collector and most of the refrigeration works. It

needs to be mounted in a sunny location, the same as any solar collector.

The refrigerator

box is the refrigerator per se and can be placed wherever is convenient, presumably

the kitchen.When the sun shines, the collector-generator produces ammonia refrigerant,

which is stored until night when the actual cooling takes place. To keep the

refrigerator cold through the day and during cloudy weather, there is built-in

storage. There are no moving parts.

In use, our

solar refrigerator is little different from any other refrigerator. Currently,

the drawbacks are a greater temperature variation since there is only one cycle

per day.

We are also

studying a very small unit where the refrigerator box is under the solar collector

so it is all one unit that is left outside. This is meant to be used for vaccines

and to be as low cost and simple as possible. We intend to include a freezer

for a limited ice-making capacity, as this simplifies the design.

We have been

looking seriously at auxiliary cooling for prolonged cloudy spells. We are trying

an external heat pipe for colder locations and thermoelectric cooling for warmer

locations. These have the advantage of being relatively inexpensive and can

be offered as add-ons instead of requiring extensive redesigning.

The other

technology, which can be implemented, is keeping the cold storage outside at

the solar collector and using a pump to circulate the cold into the refrigerator.

This would add significantly to the expense and require electricity, but would

simplify installation and keep ammonia out of the living space.

.

5.Absorption

refrigeration using solar energy

Refrigeration

is gaining very much importance in todays world. But the refrigeration that

we see us uses electricity-powered generation.

In some places

electricity is not readily available and also it is becoming costlier, so we

have to go for non-conventional type of refrigeration. Solar powered refrigeration

is useful where sunshine is in abundance in countries like India.

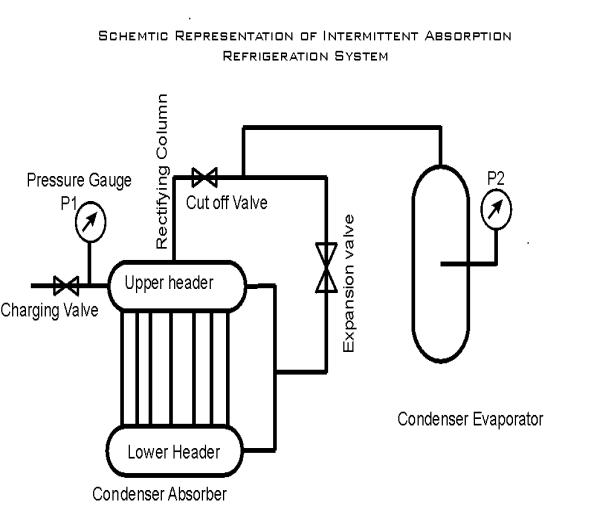

5.1 Components:

The main components of solar refrigerator

using intermittent absorption cycle are as follows. (Ref Fig 5.1.1)

The flat

plate collector acts as a generator during daytime and as absorber during night.

It consists of an upper header and a lower header of GI material and the two

headers connected by means of a number of collector tubes in between.

Ammonia

water solution is placed inside this system. During the daytime, ammonia gets

evaporated from the solution by absorbing solar energy. During nighttime, ammonia

vapor is absorbed back in the weak solution.

During the

day time ammonia vapor gets collected and condensed in the condenser evaporator.

During nighttime the condensed ammonia absorbs heat from the system to be cooled,

vaporizes and returns to the collector.

There are

totally three valves in the system one valve is in the charging line, second

valve line is between upper header and the condenser. The third valve is in

the vapor return line.

5.2 Working of the system

The generator

is charged with pre-generated amount of water and ammonia to give the required

concentration of ammonia in the solution. At the commencement of the refrigeration

period the line is opened between the upper header and the condenser, at the

end of regeneration period, the condenser is isolated from the rest of the system

and the generator absorber is allowed to cool. To carry out refrigeration the

valve between the evaporator and the collector is opened.

So

the ammonia liquid in the evaporator absorbs the heat from the water to be cooled,

gets evaporated and this vapor returns to the collector where it is absorbed

again. This cycle is repeated again the next day.

As this process of evaporation continues,

the temperature of water gets reduced and thus refrigeration is achieved.

5.3

WORKING FLUID

(REFRIGERANT)

5.3.1 Definition:

Any substance that absorbs heat through expansion or vaporization may be called a refrigerant. A broader definition may include such secondary cooling media as brine solution and cold water.

5.3.2 Requirements for a refrigerant:

These are certain desirable characteristics

which a fluid used as a refrigerant should possess.

1)

It should be non-poisonous

2)

It should be non-explosive

3)

Condensing pressure should not be excessive

4)

Low boiling temperature at atmospheric pressure

5)

High critical temperature

6)

High latent heat of vaporization

7)

Low specific heat of liquid

8)

Low specific volume of vapor

9)

It should be non-corrosive

10)

Chemically stable

11)

Ease of locating leaks

12)

Availability, low cost and ease of handling

13)

Satisfactory heat transfer and viscosity coefficients

14)

Freezing temperature of the liquid should be below any temperature

at which the evaporator might operate

15) Low compressor discharge temperatures are desirable

5.3.3

Classification of refrigerants:

The National Refrigeration Society Code,

U.S.A., catalogues all the refrigerants into three groups.

These are:

Group-One :( safest of refrigerants).

R-113, R-611,

R-11, R-21, R-114, R-12,

R-30, R-22,

R-744, R-502, R-13, R-14, R-500.

Group-Two : ( toxic and somewhat flammable

refrigerants).

R-1130, R-611,

R-160, R-764, R-40, R-717.

Group-Three :( flammable refrigerants)

R-600, R-601,

R-290, R-170, R-1150, R-50.

We used ammonia as the refrigerant.

Ammonia comes under group two refrigerants and is denoted by R-717. It was one

of the first refrigerants used.

It is used in large industrial installations. It is

colorless. Its boiling temperature at atmospheric pressure is 33.8C and the

melting point from the solid is 77.8C.It is somewhat flammable and forms an

explosive mixture with air. It attacks bronze in the presence of a little moisture

but does not corrode iron and steel. This refrigerant is extremely soluble in

water.

Ammonia leaks can be easily detected by smell

or by burning Sulphur candles or wicks, which generate a dense cloud of white

smoke in the presence of ammonia vapor.

6. THERMODYNAMIC ANALYSIS

1)

Amount of ice to be produced is 5 kg

2)

Refrigerant used is ammonia

(NH3)

3)

Absorbent used is water

(H2O)

4)

Average ambient temperature at Davangere.

During day time = 320C

During night time =

270C

5)

Amount of heat to be removed from water to convert it into

ice

Q

= mS ( ta tb) + mL

Where

M

= Mass of ice to be produced

= 5 kg

SW = Secific

heat of water = 4.187 kJ/ kg k

TA = Ambient

temperature =

+320C = 3050k

TB = Temperature

of ice =

100C = 2630K

L

= Latent heat of water

at 0oC

= 335 kJ/kg

Q

= 5 [ 4.187(305 273)

+ 2.0935 (273 263) + 335 ]

Q

= 12449.535

= 2450 kJ/kg

This is the heat load or refrigerator effect. Considering heat

flow through insulation let the heat load be equal to 2450 kJ.

(6) Condenser temperature,

tc = 400C

(7) Evaporater temperature,

te =

100C

(8) Enthalpy

of ammonia fluid at condenser temperature

h =

390.587 kJ/kg

(9) Enthalpy of vapor

ammonia at evaporator temperature

= hg =

1450.22 kJ/kg

(10)

Refrigerating effect,

Qe

= hg hf

=

145.22 390.587

= 1059.63

kJ/kg

This refrigerating effect is to be obtained

in 12 hours. Therefore, heat removed,

Qe = 2450 /

( 12 x

3600)

= 0.0567 kJ/S

(11) Let ma

be the mass of ammonia required

Qe = ma qe

Therefore,

ma = Qe/qe

= 0.0567/1059.53

= 5.35 x 105 x 12 x 3600

= 2.312 kg

This is the

mass of ammonia required to obtain the refrigerating effect for 12 hours, let it be 2.5 kg.

(12) Calculation of coefficient of performance

of refrigeration (COP)

T2 ( T3 T1)

[COP] = ---------------------------

T3

(T1 T2)

Where

T1 = Condenser temperature

= 400C = 3130k

T2 = Evaporater

temperature = 100C = 2630C

T3 = Generator temperature

= 700C

= 3430k

263 ( 343 313 )

[COP] = ------------------------------

= 0.46

343( 313 263 )

Hence co-efficient of performance

pf the system

[COP] =

0.46

6.1

Design of Flat Plate Collector

Volume and area calculations:

i) area of the corrugated sheet

= length x breath

= ( 95 x 94 ) cm2

= 8930 cm2 = 0.8930

m2

ii) volume of the upper header

length, l = 1.1 m = 110 cm

diameter,d =

4 = 10.16 cm

volume

= pd2/4 x l = p x (10.16)2/4 x 110

= 8918.05 cm3

= 8.91805 liters

iii) volume of the lower header

length ,l

= 1.1 m = 110 cm

diameter.d = 2 = 5.08 cm

volume

= pd2/4 x l

= p(5.08)2/(4)

x 110

= 2229.5 cm3

= 2.23 liters

iv) volume of the connecting pipes

length of each pipe = 112 cm

diameter of each pipe = 1.27 cm

number of pipes = 12 nos

volume

= pd2/4

x l x12

= p (1.27)2/4 x 112 x 12

= 1702.5 cm3 = 1.702

liters

v) volume of the collector

= volume of upper header + volume

of lower

header + volume of connecting pipes

= 8.918 + 2.23

+ 1.702

= 12.85 liters

CALCULATIONS F PLAE EFFICIENCY FACTOR AND OVERALL COLLECTOR EFFICIENCY:

CALCULATIONS:

(1) to find the overall heat loss coefficient,

UL

U

= Ut + Ub

Ut

= top loss coeffient

Ub

= back loss coeffient

Where

Ut

= [ (l/hpc + hrpc)

+ (l/hw + hrcs)]1

Where

hpc = Heat tranfer coefficient

from plate to cover

(glass)

hrpc = radiation

heat tranfer coefficient from plate to

cover plate

hw = heat tranfer coefficient of wind blowing over

collector

hrcs

= radiation heat transfer coeffient from cover (glass) to sky

hpc =

[(1 0.0018) (T-10)] x 1.14 dt0.31] 0.070

T = average temperature between plate and cover

dt = difference in temperature between plate and

cover

l = distance between plate and cover

hrpc = g

( T2p + T2c) (Tp + Tc)

(l/Ep) + (l/Ec)

1

Tp = plate yemperature in 0K

Tc = cover glass temperature in K

Ep = plate emittance

Ec = cover emittance

g = Stefan boltzman constant

h = Ec g (T2c + T2s)2

(Tc + Ts)

Tc = cover glass temperature

Ts = sky glass temperature + ambient temperature

hw = 5.7 +

3.8 (V)

V = velocity of wind blowing over collector

TO FIND THE HEAT LOSS COEFFICIENT, UL

Plate-to-cover spacing

= 8 cm

= l

Plate emittance

= 0.821

= Ep

Ambient air + sky temperature

= 320C = Ts

Wind speed

= 5m/sec

= v

(from wind mill data)

back insulation thickness

= 10cm

insulation conductivity = 0.065 w/m-0C

mean plate temperature =

900C

(assumed)

Ub

= K/L

= 0.065/8 x 102

= 0.8125

W/m2-0C

Ut = [(l/hpc + hrps)

+ (l/hw + hrcs)]1

Hpc = [l0.0018

(T 10)] x 1.14 dt0.310

l0.070

T = 45 + 90/2

= 67.5 0C

dt = 90 45

= 45 0C

L = 8 cms

hpc =

[( l 0.0018 x (67.5 10)] x 1.14

x (45)0.31/(8)0.07

= [ l 0.0018 (57.5)] x 1.14 x 3.25/1.15

= 2.88 W/m20C

hrpc = (T2p + T2c) (Tp + Tc)

(1/Ep) + (1/Ec) 1

= 4.87

x 108 [(90+ 73)2+(45+273)2] [(90+273)+(45+273)]

1/0.821

+ 1/0.837 1

= 6.33 W/m20C

hrcs = Ec g (T2c

+ T2s) (tc + ts)

= 0.837 x 4.87 x 108 (3182

+ 3052 ) (318 + 305)

= 5.73 W/m20C

hw

= 5.7 +

3.8 (V)

= 5.7 +

3.8 (5)

= 24.7

Ut = [1/(hpc

+hrps) + 1/(hs + hrcs)]

hpc = 2.88

W/m2

hrpc = 6.33

W/m2

hw

= 24.7 W/m2

hrcs = 5.73

W/m2

Ut

= [1/2.88 + 6.33) + 1/(24.7 + 5.73)] 1

= 7.074 W/m20C

Bottom layer coefficient, Ub:

Ub

= K/L

K

= thermal conductivity of insulation

(Glass wool)

= 0.056

~Kcal/m2hr0C

= 0.056/0.86

= 0.065W/m0C

L

= insulation thickness = 8

cm

Ub = 0.035/8 x 102

= 0.8125

UL = Ut + Ub

= 7.07 + 0.8125

= 7.9

II PLATE

EFFICIENCY FACTOR, Fp:

I WUL WUL WUL W

= + + +

Fp pdh pdk/m Cb

b + 2bF

Kp

= thermal conductivity of plate material

= 59.86

W/m0C

W = pitch =

0.1 m

|

UL |

= |

Collector heat loss co-efficient = 7.9 w/m2 |

|

D |

= |

Dia of the pipe = 1.27 cm =0.0127 |

|

H |

= |

Average heat transfer coefficient of fluid to tube wall = 68.86 w/m2 |

|

K |

= |

Length extension coefficient = 44.986 W/m 0C |

|

Cb |

= |

Air bond conductance between collector Plate and Tube =27.68 W/m0C |

|

A2 |

= |

UL 7.90 ----- = ---------------------- = 268.43 KpM 58.859 x 0.0005

|

|

A |

= |

16.38 |

|

b

b |

= = = |

W B/2 0.1 0.0177/2 0.04115 m |

|

Ab |

= = |

16.38 x .04115 0.0674 m |

|

F |

= |

Tanh (ab) tanh( 0.674 ) ------------ = ------------------- = 0.871 ab 0.674 |

|

WUL ------- pdh |

= |

0.1 x 7.9 ---------------------------------------- = 0.2875 p x 12.7 x 103 x 68.86 |

|

WUL ------- pdk/m |

= |

0.1 x 7.9 ----------------------------------------------------- p x 12.7 x 103 x 44.986/0.005

|

|

|

= |

0.0022 |

|

WUL ---------------- Cb

|

=

= |

0.1 x 7.9 ---------------------------- = .0285 27.683 0.0285 |

| W ------------------ b + 2bF |

=

= |

0.1 ----------------------------------------- 0.0177 + 2 x 0.04115 x 0.871

1.12 |

|

I --------- Fp

|

= |

WUL WUL WUL W ------- + -------- + --------- + ---------------- pdh pdk/m Cb b + 2bF

|

|

|

= |

0.2875 + 0.0022 + 0.0285 + 1.12 |

|

Fp |

= = |

1/1.43 0.6953 |

PLATE EFFICIENCY

FACTOR. Fp = 69.53 %

QUANTITY OF

AQUA AMMONIA USED

Since the volume of the collector

is 12.85 liter, the quantity of ammonia solution to be used is about 12 liters.

| PAGE 2 | END | ||||||||

2002©Arma Technologies, all rights reserved disclaimer & copyright

If you find any of your copyrighted content email us the same along with proper proof ,the requisite material will be removed within a week